Bioprocess technology

Advancing bioprocess technology for quality and efficiency in biopharmaceuticals

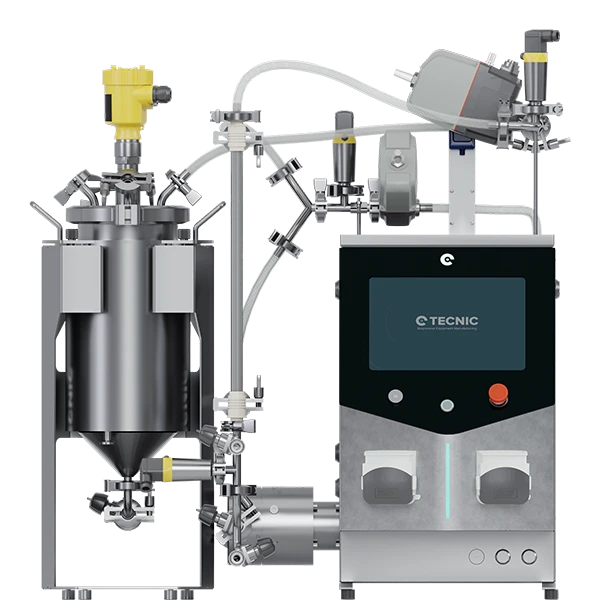

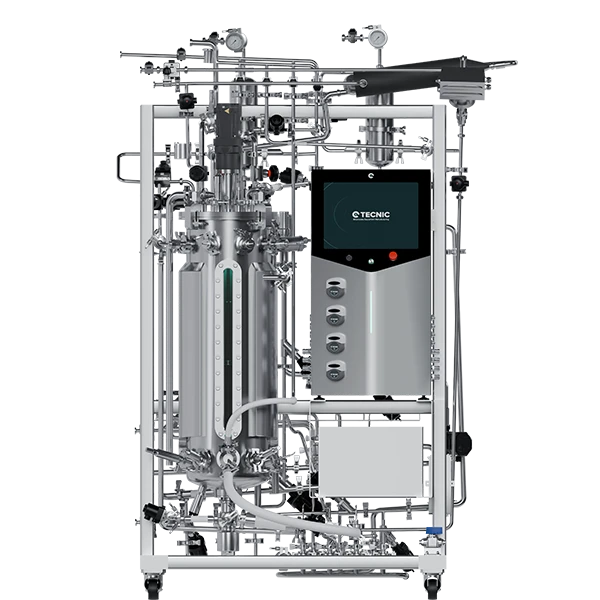

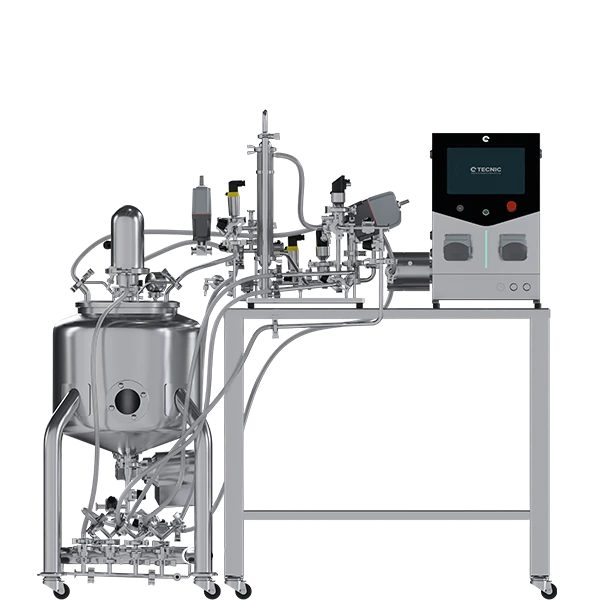

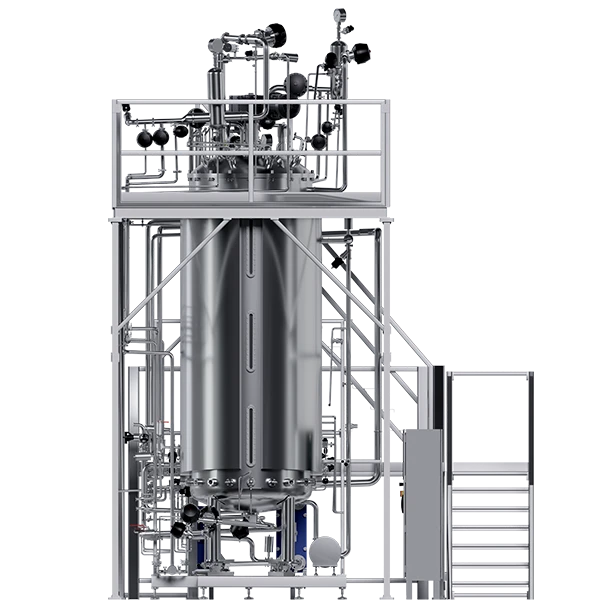

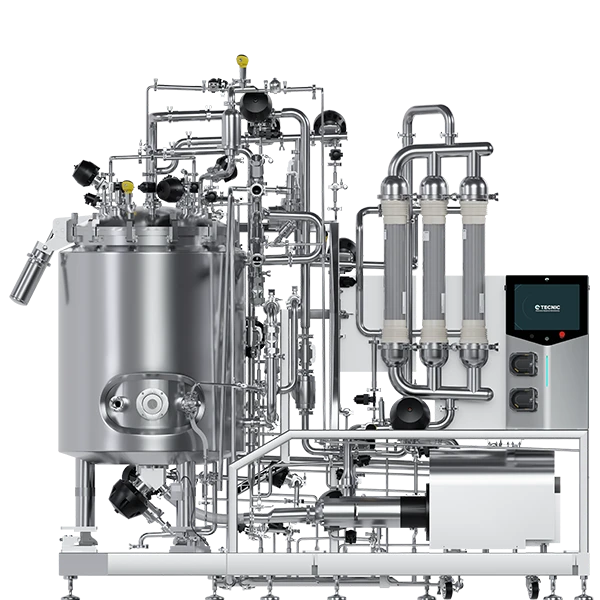

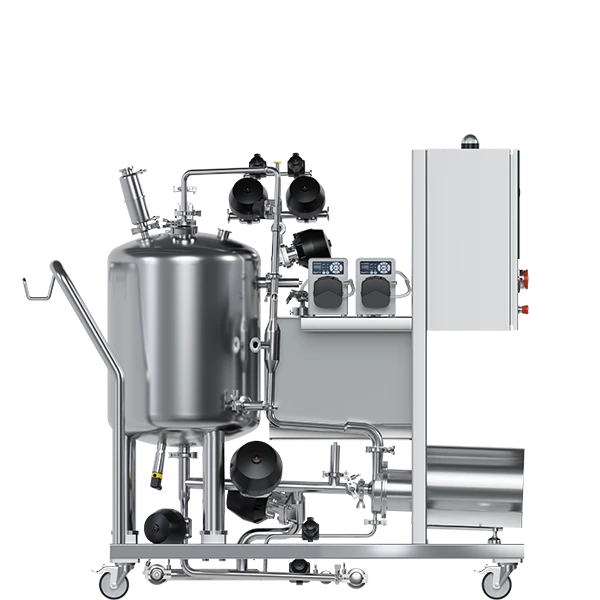

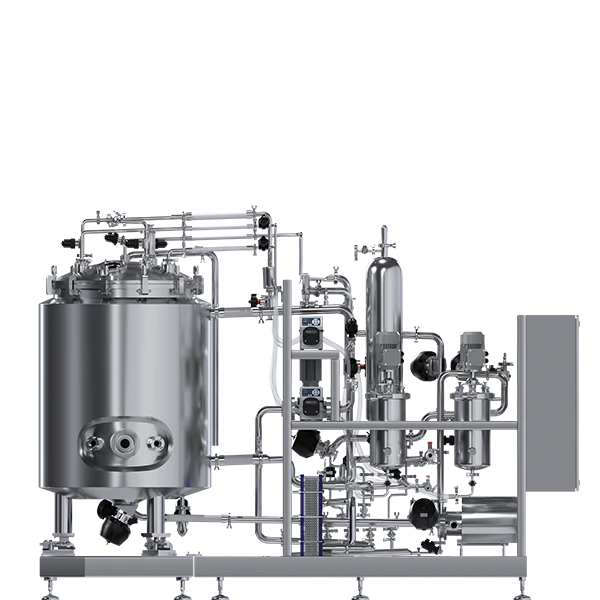

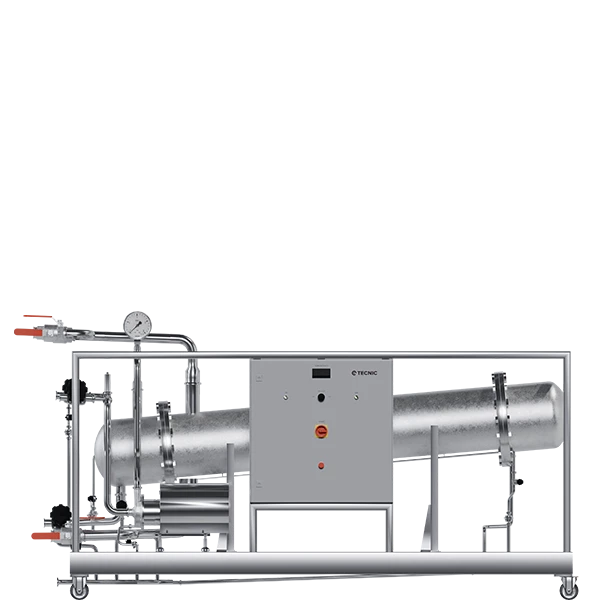

Optimize your bioprocess applications with our solutions, ensuring smooth start-up and workflow efficiency. Our bioprocess technology extends from specialized equipment designed for laboratory applications, including bioreactors and tangential flow filtration systems, to scalable solutions that meet the demands of full-scale production, ensuring a seamless transition from research to market.

Moreover, through rigorous testing of our bioprocess technology, we ensure product reliability and consistency. As a result, this approach not only enhances your production efficiency but also plays a crucial role in accelerating clinical development and significantly reducing costs.